Centrifugal Pumps: Their Applications and Advantages

Categories Of Concrete Pumping Services

January 25, 2019

The Pros Of Using A Concrete Pump

February 15, 2019Centrifugal Pumps: Their Applications and Advantages

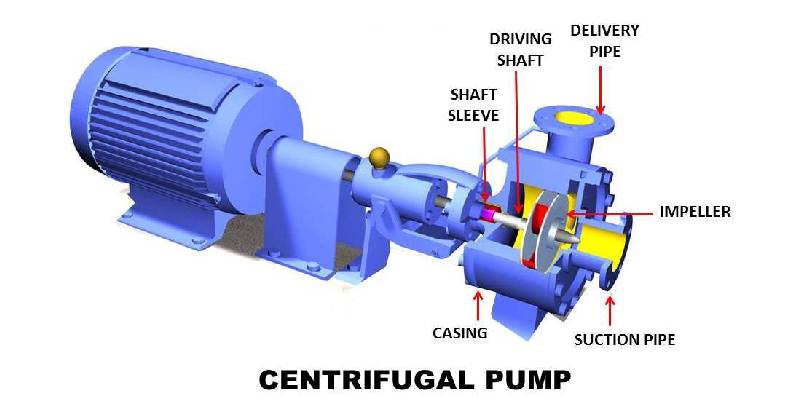

Centrifugal pumps have a straightforward design, and their production efficiency is supreme which has made the most commonly used pumps in the world. Operating them is easy plus they have an assorted range of capacity and head with each producing a reasonable flow rate. Centrifugal pumps are not only perfect for high flow rates but also for pumping low-viscosity fluids.

How do centrifugal pumps work?

These pumps come attached with 1 or more impellers. Connected to the shaft, the impellers rotate and cause the movement of impellers in the side chamber. This creates a flow of water which builds a low pressure in the inlet chamber which, in turn, suctions water from the intake side. As water is pumped out from one side, it is taken in from another.

Where can centrifugal pumps be applied?

Centrifugal pumps have a diverse range of uses. They are appropriated in municipal operations, scientific labs, commercial sector, industrial plants, and residential complexes. Some examples are:

• In the water treatment industry, a diaphragm type centrifugal pump is used. It meters accurate amounts of liquid. The aim of it is to treat:

o drinking water

o boiler water

o swimming pool water

o wastewater

These pumps can be applied for any application that necessitates high water pressure or places where the pump doesn’t need to have a seal.

Some other places, sectors, and industries where centrifugal pumps are appropriated are:

• distilleries

• dairy farms

• construction

• production lines

• automotive companies

• food service and processing

• utility companies for turbines

• chemical processing and laboratories

What are the benefits of centrifugal pumps?

Centrifugal pumps do not have a drive seal which implies there is never a chance of a leak. Ergo, centrifugal pumps are ideal for applications that work with hazardous materials. Furthermore, the lack of drive seal also means:

• no friction loss

• no noise

• no wear and tear

The liquid that is pumped is entirely separated from the pump drive which makes the machine almost 100% efficient. In other words, complete motor power is used for pumping power.

Another advantage of centrifugal pump lies in the air gap. The pump chamber and the motor are divided by the air gap which signifies that there is no heat transfer. Moreover, it is not possible for the fluid to seep from the pump into the motor. Lastly, the magnetic coupling prevents damage to the pump.

Read More : Essential Plumbing Fixtures That Must Work During Power Cuts