The Classification Of Pumping Services In India

Popular Pump Dealers In India

April 16, 2018

Categories Of Concrete Pumping Services

January 25, 2019The Classification Of Pumping Services In India

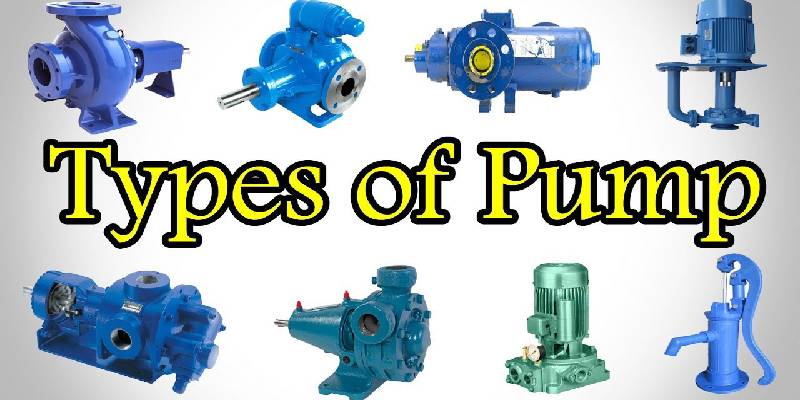

A device that moves fluid from one location to another using a mechanical action is called a pump. The first pump is said to have originated in ancient Egypt. It was called a shaduf, and the device was utilised to transport water. Later on, many other civilisations used it to lift water. Over the centuries, there have been numerous improvements over the first pump which means there are an array of pumps available as of today.

In India, though pumps are used for multiple applications and diverse industries, there are two primary categories – Dynamic and Positive Displacement.

Two Major Classifications in Pumping Services

1. Dynamic Pumps

a) The most commonly found pumps are the centrifugal pumps. They are employed all over the world because they have a simple working principle. Furthermore, the cost of manufacturing them is relatively economical.

b) A pump that can operate even when underwater is called a submersible pump. It is also known by other names such as stormwater pumps, sewage pumps, and septic pumps.

c) More a system than a pump, a fire hydrant pump system is called by additional names such as fire pump, fire water pump, and hydrant booster. The fire pump is made of one centrifugal pump along with separate components like a driven motor (electric or diesel) and control panel.

2. Positive Displacement Pump

a. There are two chief diaphragm pumps: Air-operated and Mechanical. AOD pumps run entirely on air which makes them perfect for rough and harsh conditions. They are ordinarily used in coal mines, chemical transfers, food manufacturing and transfer of liquids with high solid content.

b. For high pressures and pumping liquids with extreme viscosity, gear pumps are employed. They transfer the fluid through gears which come in and out of a mesh creating a non-pulsating pumping action.

c. For steady dosing and blending of liquids, a peristaltic pump is applied. They can pump a diverse amount of fluids including toothpaste and chemicals. They are extensively employed in

i. Water treatment

ii. Chemical processing

iii. Food processing industries

d. In F&B and pharmaceutical applications, lobe pumps are utilised. They have excellent sanitary qualities, reliability, and superb efficiency. Plus, they are resistant to corrosion and have remarkable CIP (clean-in-place) and SIP (sterilise-in-place) qualities.